-

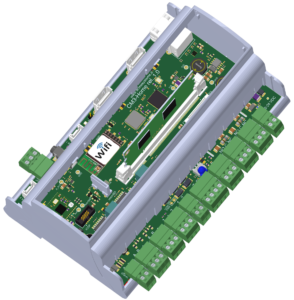

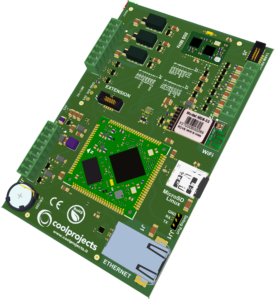

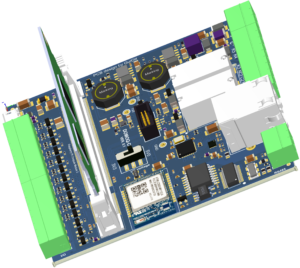

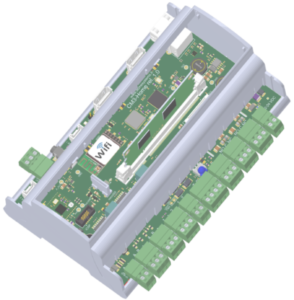

OpenHAB DIN rail controller

CM3-Home OpenHAB edition is a ready-to-use DIN rail home & building automation controller based on Raspberry Pi 3 industrial module and OpenHab software

-

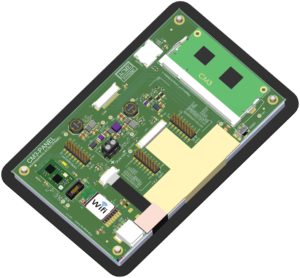

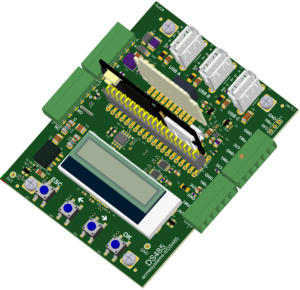

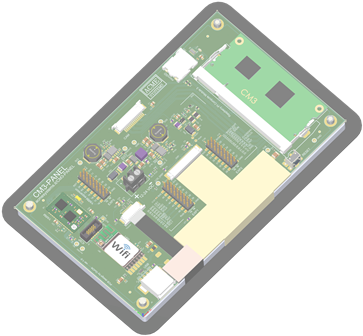

CM3-PANEL

CM3-Panel is a thin panel PC based on Raspberry Pi 3 lite industrial module thought to be integrated on the front panel of your devices

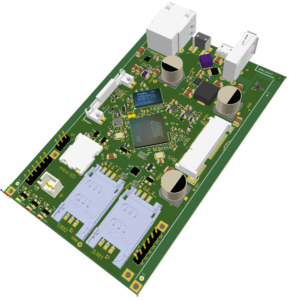

Products

We offer automation solutions for increasingly efficient buildings thanks to the state of the art technology

Design

We design customized solutions that best meet your needs and those of your projects

Maker Space

We take care of the Makers and we have dedicated a section of our site to their curiosity and the desire to experiment

Hardware Pills

Our tutorials have three keywords: automation, robotics, electronics

Who I am

GUIOTT (Guido Ottaviani), (Author/Designer/Developer for electronics-firmware-robotics) He deals with electronic design and embedded system firmware for Robotics and industrial and civil applications, as well as technical disclosure on the internet. e-mail: [email protected]

International publications

Below you can find the link to an interesting interview about robotics that has seen me in the specialized magazine "Circuit Cellar" where you can find some of my articles

Products

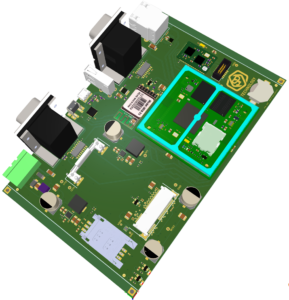

CM3 - HOME

CM3-Home OpenHAB edition is a ready-to-use DIN rail home & building automation controller based on Raspberry Pi 3 industrial module and OpenHab software

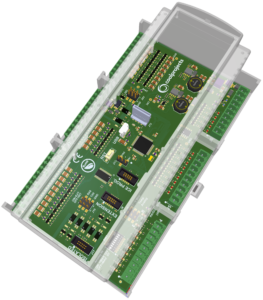

CM3 - PANEL

7" terminal for Raspberry Pi Compute Module 3, a thin panel PC based on Raspberry Pi 3 lite industrial module thought to be integrated on the front panel of your devices